Pet ownership continues to rise as people search for comfort and companionship. Pets have become part of the family, and pet parents want to ensure and maintain their healthy lives. Shoppers spend time researching and reading about the best nutrition for their pets and want to know that what they purchase is of the same quality as the food they eat themselves.

Pet food manufacturers are the leaders who ensure safe, responsible, and sustainable food supplies for the world’s dogs and cats.

Responsibility from Farm to Bowl

Consumers want information and assurances about what they feed the pets they love. They seek confidence that their pet food is safe and nutritious. They want to know that every bit of food going into their pet’s bowl is made with responsible and sustainable processes for our planet and all who inhabit it.

Pet food manufacturers across the country are expected to continuously improve the supply chain, answer questions, and provide assurances to pet owners about ingredients and nutrition. With increasing demand comes increased responsibility for transparency, reducing risk, and providing the information and confidence customers require.

With increasing knowledge and concern for safety and sourcing, consumers make pet food choices based on a brand’s reputation.

Your reputation depends on the quality of the product you produce. The stakes are high.

Confidence and Your Reputation

Your success as a pet food manufacturer depends on overcoming and staying ahead of industry changes and keeping up with changing consumer expectations.

You’ve invested a lot in your brand and your reputation – all while growing your business for the future.

You need a partner you can count on for the quality, accuracy, and safety of the supply chain to maintain consumer confidence and your reputation.

Cargill wants to be that partner. We want to help you thrive.

Cargill: Your Partner and Advocate

We are pet owners too. Like you, we want what’s best for our furry companions. For more than 150 years, our family-owned company has put people and animals first while building a legacy of customer trust and confidence.

We are in the fields, labs, and production facilities around the world every day. We listen, learn from data, and guide pet food manufacturers to achieve success amid constant change.

Cargill is with you ensuring consumer confidence in where their pet food comes from and how it’s produced, from farm to bowl.

Like you, we take our responsibility to the pet food chain seriously. We’re vested in it, and we’re vested in you.

Animal Nutrition: From Feed to Food

Vitamin-trace mineral premixes are essential for pet nutrition, and the need for products with small inclusion rates continues to increase. Cargill met the challenges of consumer confidence with a determination to raise the bar on premix production and a new plant.

Raising the Premix Bar – Introducing Lewisburg West Premix Plant

Cargill’s new non-medicated animal nutrition plant sets a new standard for pet food premix production. It provides you with unmatched confidence in pet nutrition, raising the bar for accuracy, safety, and quality.

Plans for Lewisburg West began with listening to customers, studying trends, and using data to identify future demands. These insights led to a unique design for a new facility.

“We’ve brought together lessons learned from our own and other facilities across the world. Cargill was determined to push toward the future, and every aspect of the design process for this plant will have a global impact on pet food purity, safety, reliability, and nutrition.”

Jack O’Connor, Production Excellence Leader

Dubbed the “Lewisburg West” facility because of its location, this future-ready premix plant was designed with pet food safety as a top priority.

Cargill purchased the site from a major pet food manufacturer, and the design team looked for ways to repurpose much of the existing infrastructure. Lewisburg West is built on the foundation of sustainability from the ground up and continuing through every design, process, and production decision.

Designed to Deliver Confidence in Animal Nutrition

The new Lewisburg West facility builds upon Cargill’s complete offering of ingredients and services to optimize pet nutrition. Cargill consultants and technical support provide customers with precision nutrition formulations to bring the highest quality premixes into pet food production.

Trusted Ingredients

Cargill’s reliably sourced pure, traceable, and safe ingredients from around the world arrive at the receiving docks of Lewisburg West to begin the process of making a premier pet premix.

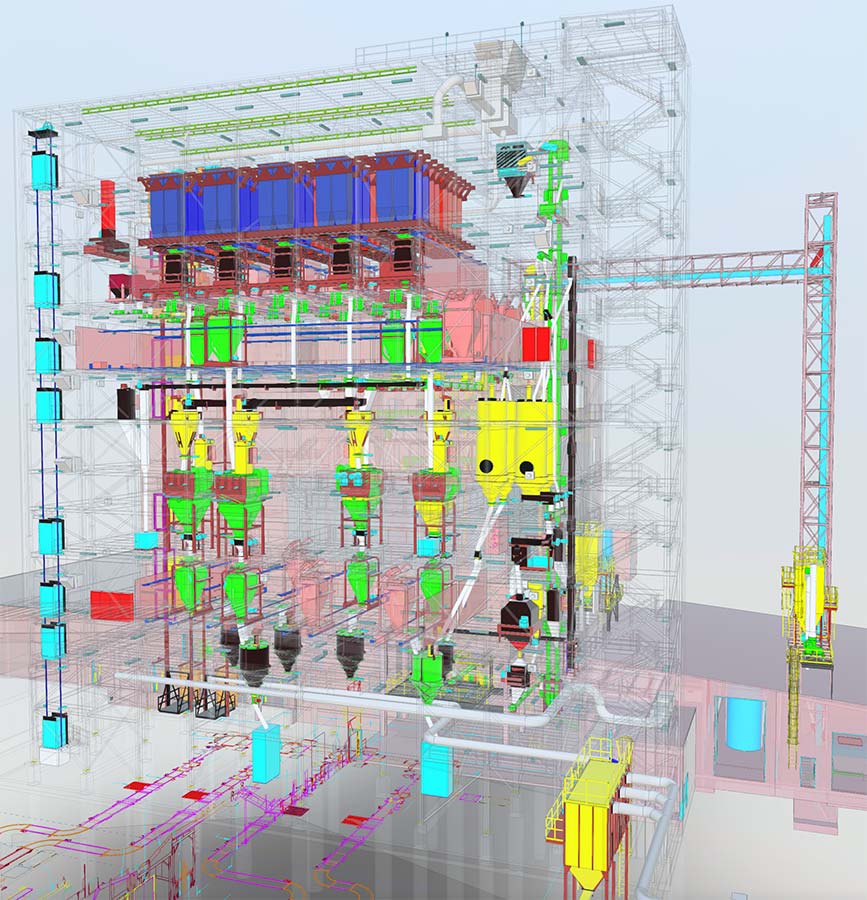

A Look Inside Lewisburg West

Designed and Built to Make a Difference in Animal Nutrition

“We set out to design and build a premier premix plant. Over six years, we gathered best practices and cutting edge partners from around the world and here in the U.S. to build a plant that raises the bar for premix production and animal nutrition.”

- Dean Barker, Operations Director

Cargill’s teams carefully planned the plant’s advanced technology and design over several years. These high standards, meticulously executed, ensure productivity and protection for customer brands now and in the future.

Advanced technology and features ensure customer confidence in the accuracy, traceability, quality, and sustainability of premix ingredients and production.

“The key features of the facility were ultimately decided on by our customers. We spent time translating the voice of our customers into specifications. Each time we went through an iterative design, we would come back to those specifications to make sure they matched up to our plans.”

- Jack O’Connor, Production Excellence Leader

A combination of soft, flexible hoppers and stainless steel hoppers are used throughout the plant to keep the product flowing well and protect the premix ingredients from cross-contamination.

Localized dust control ensures the ingredients remain in the system and also in the finished product. This is different from typical dust collection systems that remove ambient dust from the process where it inevitably ends up in the surrounding environment or a landfill.

Ensuring Food Safety and Purity from Dock to Dock

- Two separate unloading pits for trucks delivering ingredients provide separation of proteins from non-proteins.

- The non-medicated environment of Lewisburg West ensures a non-medicated premix that meets customer specifications.

Locked access points provide additional security throughout the production system. These access points can only be opened when an ingredient being added is scanned, and the corresponding barcode matches the correct access point to unlock the lid.

- In the final production steps, the finished premix is again measured for accuracy before being dispensed with an automated packaging system for each production line.

- Cargill’s teams document safety, purity, and traceability from the dock, receiving the ingredients to the premix products’ shipping dock. These records are readily available to customers.

The Automated Weighing and Dosing System of Lewisburg West ensures gram-precision dosing of premix nutrients for accuracy.

Lewisburg West Premix Production

The use of unique problem-solving designs from Diamondback Technology™ works throughout production equipment and processes. This technology handles fine granules during mixing, delumping, and before packaging to prevent the separation of ingredients for a better premix.

- Barcoding, weight checks, and detailed record-keeping throughout the production process enable traceability and ensures that everything that goes into the premix stays in the premix.

- Before the product leaves the plant, there is a final checkpoint to confirm the order and the production match. This confirmation is recorded and accessible to customers for traceability and quality assurance.

Cargill puts the innovations of Lewisburg West to work for your business.

Partner with Cargill to strengthen your bottom line, your brand, and your future.

Cargill sets the new standard for precision pet premix production with Lewisburg West’s capabilities and connects it to our teams of nutritionists’ and consultants’ great work to support your business.

“We in the Pet Unit of Cargill are nearly all pet owners. We work closely with customers developing formulas and concepts for new pet foods. So we think and breathe “pet” every day.

With over 68 business units, Cargill can provide ingredients from farm to bowl. Lewisburg West brings us into the very beginning of pet food manufacturing with a non-medicated environment, gram-precision dosage of vitamins and minerals, and complete traceability. ”

- John Dickerson, Technical Sales Leader

“Pet owners want the same quality and quantity of nutrition they put on their own plates, in their pet’s bowl. Today, vitamin-trace minerals are a huge part of a pet’s diet. Pet owners want them to stay healthy, and they look to the ingredient label on the bag and the reputation of the brand.

They spend more on pet food they can trust.

Our customers, large and small, produce truckload after truckload of pet food. We understand that keeping up with demand is enough of a challenge. We can help with your supply and give you the peace of mind that Lewisburg West’s non-medicated facility will deliver a premier pet premix.”

- Andi Dell, Sales Manager

“We understand that food producers manage a lot of challenges; labor, weather, the economy, and more. Animal nutrition is not their biggest concern. Our customers can count on Cargill to do everything we can to contribute to this important part of every business, no matter the size.”

- Arturo Garcia, PhD, Poultry Nutritionist

“Our customers love agriculture and are vested in their business. They want a partner that is easy to do business with and someone they can trust. They are proud to have their name on the food they produce, and we’re proud to help them continue in success.”

- Mike Warsco, Strategic Account Manager

“Accuracy and precision in vitamin-trace mineral (VTM) blending is critical to animal performance and health. For example, VTMs typically account for 2% or less of the total volume of feed consumed by pigs; however, that small package packs a mighty punch. Over 50% of the total ingredients that make up a complete swine feed are delivered via VTMs, including critical nutrients such as Vitamins A, D, and E, zinc, and selenium, and often key feed additives such as phytase and other enzymes.”

- Chad Pilcher, PhD, Swine Nutritionist

Contact your Cargill representative for more information on how you can get the most out of this new technology to support your business, your bottom line, and your brand.

Together, we will nourish the world’s pets with solutions that help you and your operation thrive.

Diamondback Technology™ is a trademark of JR Johanson, Inc.

©2021 Cargill, Inc. All rights reserved.